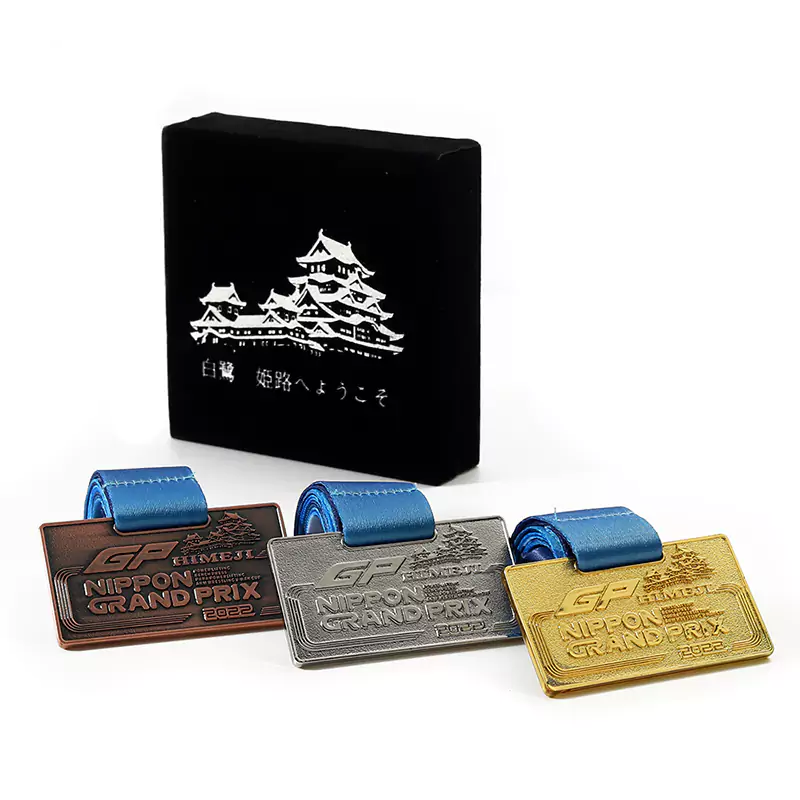

Metal medals, as exquisite works of art, hold significant symbolic meaning and honor in various competitions, events, and award ceremonies. The purpose of this article is to provide a comprehensive guide on how to customize the production of metal medals to meet customers' personalized needs.

Ⅰ.Understanding Requirements of Metal Medals

1.Effective Communication

Establish clear and open communication channels with customers to understand their specific requirements and preferences for metal medals. This includes the purpose of the metal medals design elements, dimensions, engraving details, and other personalized aspects.

2.Design and Artwork Confirmation

Collaborate closely with customers to develop the design concept and artwork for the medals. Utilize computer-aided design software to create detailed visual representations and ensure alignment with customer expectations.

II. Custom Medal Design Mold Making and Process Flow

1.Mold Making

Produce molds for metal medals based on customer design requirements. Select high-hardness and wear-resistant materials such as steel. Utilize precision cutting and engraving techniques using CNC machines to ensure accuracy and reliability of the molds.

2.Material Selection and Preparation

Choose suitable metal materials such as copper medals, zinc alloy medals, or stainless steel medals, based on the requirements of the medals. Ensure the materials have good plasticity and corrosion resistance. Conduct strict inspections and preparations for the materials before production to ensure stable and consistent supply.

III. Custom Medals Production Process

1.Material Cutting

Use automated cutting equipment to cut the metal materials into the basic shape of the medals, based on the mold's shape and dimensions. Ensure precision and consistency in the cutting process.

2.Stamping and Forming

Place the cut metal materials into stamping machines and use appropriate dies to stamp and form the metal. Adjust stamping parameters and processes to ensure accuracy and consistency of the medals.

3.Surface Treatment

Apply surface treatments such as sandblasting, polishing, and electroplating to the stamped metal medals. Choose suitable surface treatment methods based on customer requirements and design needs to enhance the appearance and gloss of the medals.

4.Engraving and Inscription

Use engraving tools or laser engraving equipment to engrave and inscribe on the medals. Fine-tune the texts, patterns, or details on the medal's surface according to customer demands, adding personalization and uniqueness.

IV. Quality Control and Inspection

1.Raw Material Inspection

Conduct rigorous inspections on the raw materials before production to ensure they meet the quality requirements. This includes visual inspections, dimensional measurements, and material testing.

2.Production Process Control

Implement strict quality control measures during the production process. Monitor stamping and forming parameters and processes to ensure consistency and accuracy for each medal.

3.Finished Product Inspection

Perform visual inspections, dimensional measurements, and quality testing on the stamped metal medals to ensure they meet the standards and customer requirements.

4.Sampling Inspection

Conduct sampling inspections by randomly selecting samples from the batch production for testing to ensure consistent and reliable product quality.

V. Packaging and Delivery

1.Packaging

Properly package the batch-produced metal medals, such as using boxes or pouches, to protect the products from damage during transportation and storage. Use appropriate protective materials and fillers to safeguard the medal's surface and shape.

2.Delivery

Select suitable logistics channels and arrange appropriate delivery methods based on customer requirements and geographical locations. Ensure the safety and timely delivery of the products to meet customer needs.

VI. After-Sales Service and Feedback Collection

1.After-Sales Service

Provide comprehensive after-sales services to customers, including product quality assurance, repairs, and replacements. Respond promptly to customer inquiries and complaints, actively resolving any issues to ensure customer satisfaction.

2.Feedback Collection

Regularly communicate with customers to gather feedback on product quality and service. Through feedback collection, identify and address any issues in a timely manner, continuously improving product quality and customer satisfaction.

Conclusion

By understanding customer requirements, mold making, process flow control, quality inspection, packaging, and delivery, metal craft manufacturers can efficiently customize and produce metal medals in bulk. With advanced technology and rigorous quality control, manufacturers can meet customers' personalized needs and provide high-quality products and services.

By optimizing production processes,introducing new production equipment and technologies, and training employees to enhance their skill levels, manufacturers can further improve production efficiency and product quality. Additionally, maintaining close cooperation and communication with customers, staying informed about market demands and trends, and making timely adjustments to production strategies and product designs are essential to meet customers' ever-changing craft metal products needs.

Extended Reading

Hesank Crafts Co., Ltd., located in Wenzhou, is a professional and reputable manufacturer specializing in customized production of metal medals. We possess advanced craftsmanship and equipment, dedicated to providing customers with high-quality customized metal medals.

Our professional team will provide creative suggestions based on customer requirements and design intentions. Through the use of CAD technology, we ensure the design concepts are accurately presented, aiming to achieve customer satisfaction.

We sincerely welcome customers to contact us or send inquiries in a timely manner. Our sales team will respond actively to customer needs and provide detailed product quotations and technical support. We promise to earn customers' trust and satisfaction through high-quality products and services, and we look forward to a successful partnership with our customers. Hesank Crafts Co., Ltd. in Wenzhou is excited to cooperate with you!